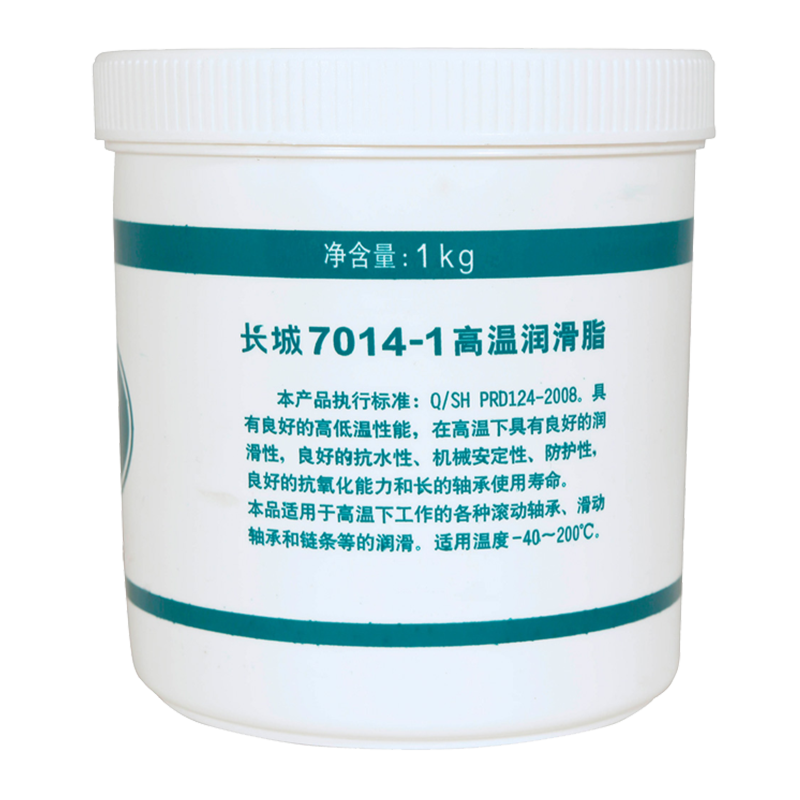

Sinopec 7014-1 High-Temperature Grease 1 kg

Packaging specifications:1 kg

Order Hotline:+86 18624936708

Applicable temperature range: -40°C to 200°C.

Sinopec 7014-1 High-Temperature Grease

Overview:

Sinopec 7014-1 High-Temperature Grease is made from synthetic oil thickened with an organic thickener and refined with various antioxidant and anti-corrosion additives.

Performance Features:

◎ Excellent oxidation stability prevents grease deterioration at high temperatures

◎ Excellent mechanical stability and suitable adhesion prevent grease loss

◎ Excellent high and low temperature performance ensures normal bearing operation over a wide temperature range

◎ Excellent water washout resistance makes it suitable for bearing lubrication in humid environments

◎ Excellent lubricity protects bearings and reduces wear

◎ Excellent overall performance ensures a long bearing life

Technical Specifications:

This product conforms to the following specifications:

◎ Q/SHPRD124-2008

Applications:

◎ Designed specifically for high-temperature bearings, it is suitable for lubricating high-temperature bearings such as auxiliary boiler rotating nozzle bearings in large chemical plants, sleeve bearings in plastic extruders, induced draft fans in cracking furnaces, regeneration gas compressors, and rolling and sliding bearings in various high-speed, high-temperature machinery, such as stretching tenters, hot melt blowers, heat-setting ovens, bakers, and high-temperature dyeing vats. It also lubricates gears, chains, and clutches operating in high-temperature environments.

◎ Applicable temperature range: -40°C to 200°C.

Typical Data:

| Item | Sinopec 7014-1 High-Temperature Grease |

| Appearance | Light brown, smooth and uniform ointment |

| Drop point, °C | 316 |

| 1/4 cone penetration, 0.1mm | 67 |

| Pressure separation oil, % (m/m) | 6.41 |

| Evaporation degree ( 200℃,1h), % (m/m) | 2.66 |

| Steel mesh oil separation ( 100℃, 24 h), %(m/m) | 1.65 |

| Similar viscosity (-40℃, 10s⁻¹), Pa.s | 653 |

| Water repellency performance (at 38℃ ± 3℃), % (m/m) | 1.83 |

| Corrosion (T3 copper sheet, 100℃, 3 hours) | Pass |

Comparable foreign products:

Comparable performance for high-temperature bearing lubrication to the following foreign brands:

| Sinopec | Japan | The United States | Germany |

| 7014-1Grease | Marusan WR-3 | Dow corning 44 | ISOFLEX NBU 15 |

Caltex Unitemp Grease 550 | |||

Mobiltemp SHC 100 | |||

Mobiltemp SHC 32 |

Aplication Examples:

◎ Widely used in high-temperature fan bearings and speed control screws in heat-setting machines at printing and dyeing plants in Jiangsu, Zhejiang, and Guangdong.

◎ A chemical group company has successfully replaced imported grease with effective results on boiler nozzle bearings in large fertilizer plants (bearing temperatures exceeding 200°C and speeds of 10,000 rpm).

Precautions:

◎ Do not mix with other greases. Physical or chemical reactions may occur between different greases, significantly degrading performance.

◎ Close the cap immediately after use to prevent the ingress of moisture, dust, and other impurities.

◎ When lubricating parts that come into contact with non-metallic materials such as rubber, plastic, and paint, perform a material compatibility test beforehand.

Packaging:

◎ 1kg plastic box or customized packaging.